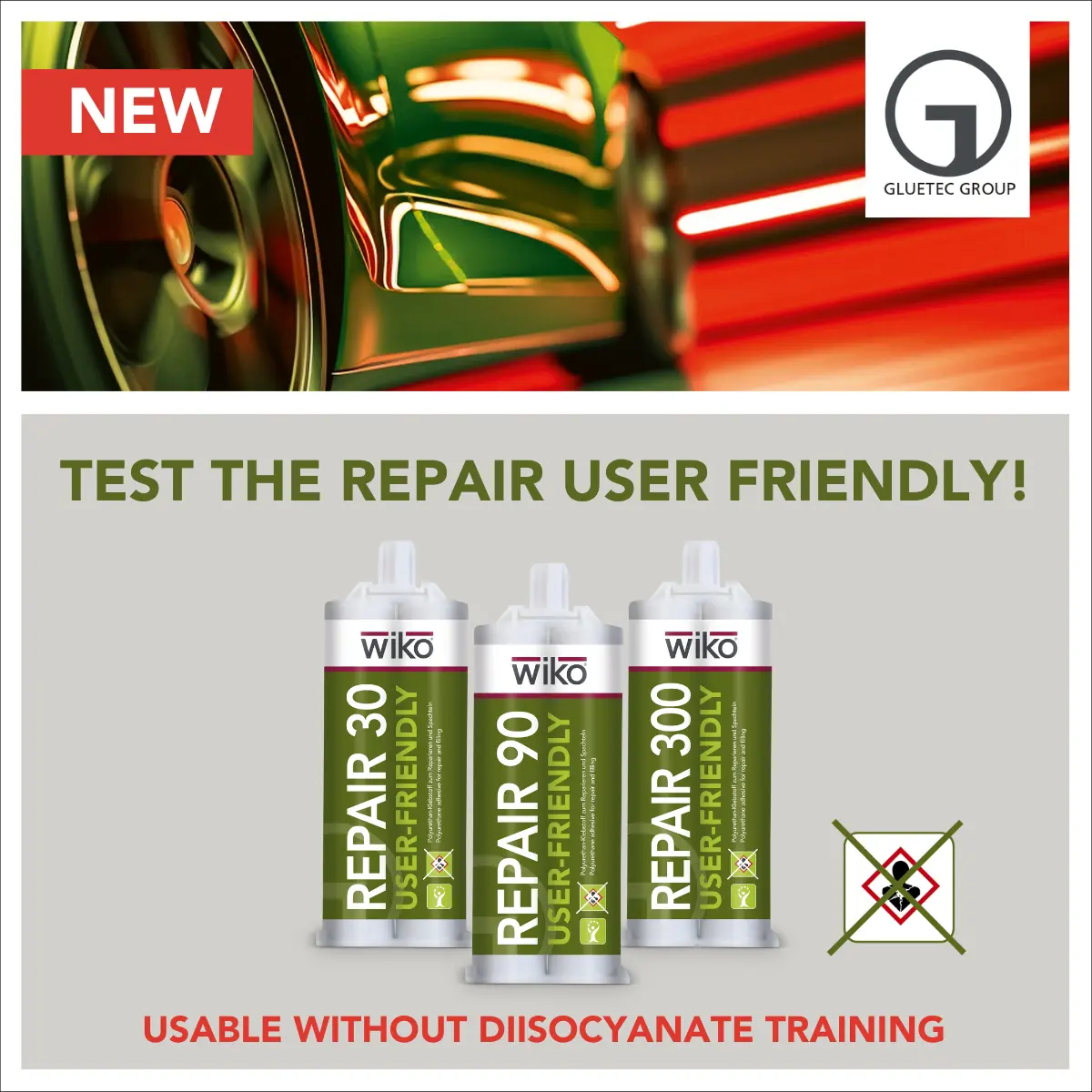

NEW: Repair adhesive WIKO® REPAIR USER FRIENDLY

August 9, 2023

Gluetec News

2023, Products

The new power package.

Today's vehicles consist of a high proportion of plastics and other lightweight components. As a result, visually flawless plastic repairs on vehicles are becoming more and more important. Before replacing an entire bumper, for example, smart adhesives offer a sustainable, visually flawless and above all functional repair solution.

You are looking for a high-performance adhesive for your demanding repairs, but you are afraid of the dangers in handling and the costs for the necessary occupational safety of your employees? Then we have just the thing for you:

This is where the new power package from WIKO® comes into play! The new WIKO® REPAIR USER FRIENDLY adhesives convince with a new type of 2-component polyurethane, which on the one hand creates particularly strong bonds and at the same time is very user-friendly and low-marking. Extensive GLUETEC laboratory tests prove this high-strength connection of PVC components by substrate fracture. This means WIKO® REPAIR UF is so strong that it is more likely that the component will break, but the adhesive bond will withstand the strongest forces. No other comparable adhesive could achieve the same result in this GLUETEC extreme test! This makes WIKO® REPAIR UF the ultra-strong solution for cosmetic bonding of a wide variety of plastics as well as metals - without the need for an isocyanate licence for the user!

The latest generation of WIKO® REPAIR adhesives, available in 30 s, 90 s and 300 s working times, are specially designed for the wide range of applications in vehicle construction and the repair of bodywork parts such as spoilers, skirts and bumpers. The black colour delivers visually sophisticated results for exterior and interior bonding. The new, user-friendly formulation ensures that the material can be easily modelled during the pot life.

Advantages WIKO® REPAIR UF:

Today's vehicles consist of a high proportion of plastics and other lightweight components. As a result, visually flawless plastic repairs on vehicles are becoming more and more important. Before replacing an entire bumper, for example, smart adhesives offer a sustainable, visually flawless and above all functional repair solution.

You are looking for a high-performance adhesive for your demanding repairs, but you are afraid of the dangers in handling and the costs for the necessary occupational safety of your employees? Then we have just the thing for you:

This is where the new power package from WIKO® comes into play! The new WIKO® REPAIR USER FRIENDLY adhesives convince with a new type of 2-component polyurethane, which on the one hand creates particularly strong bonds and at the same time is very user-friendly and low-marking. Extensive GLUETEC laboratory tests prove this high-strength connection of PVC components by substrate fracture. This means WIKO® REPAIR UF is so strong that it is more likely that the component will break, but the adhesive bond will withstand the strongest forces. No other comparable adhesive could achieve the same result in this GLUETEC extreme test! This makes WIKO® REPAIR UF the ultra-strong solution for cosmetic bonding of a wide variety of plastics as well as metals - without the need for an isocyanate licence for the user!

The latest generation of WIKO® REPAIR adhesives, available in 30 s, 90 s and 300 s working times, are specially designed for the wide range of applications in vehicle construction and the repair of bodywork parts such as spoilers, skirts and bumpers. The black colour delivers visually sophisticated results for exterior and interior bonding. The new, user-friendly formulation ensures that the material can be easily modelled during the pot life.

Advantages WIKO® REPAIR UF:

- Ultra-strong adhesion to all common materials in the automotive industry: On PVC, highest strength compared to competitor products (substrate breakage according to GLUETEC laboratory test)

- Fast repairs of various plastics and other materials such as metal, wood, stone and concrete

- High gap filling capacity for difficult bonding conditions

- Excellent resistance to water, a wide range of acids and alkalis, oil, fuel and solvents

- The bonds are impact resistant, weatherproof and ageing resistant

- Can be easily reworked (drilled, sanded, cut) and painted over

- High safety standard for the user:

Low-labelling (not classified as "probably carcinogenic")

No isocyanate licence necessary

Colour: Black

Advantages GLUEMIX mixing nozzle:

You want to see the power of the new adhesives for yourself right away? No problem! Ask for a free product sample now - including innovative GLUEMIX mixing nozzles, the corresponding technical data sheets and the safety data sheets.

We are looking forward to your feedback on the new WIKO® REPAIR UF adhesives. Your GLUETEC customer advisor will be happy to answer any further questions and take orders: info.de@gluetec-group.com, Tel. +49 9369 9836-0.

- 2.5 cm shorter than comparable mixing nozzles

- Narrower mixing elements and three interference points for more homogeneous mixing - even of adhesive components with different viscosities

- Easy handling due to low pressure drop

- Exact dispensing and precise dosing

You want to see the power of the new adhesives for yourself right away? No problem! Ask for a free product sample now - including innovative GLUEMIX mixing nozzles, the corresponding technical data sheets and the safety data sheets.

We are looking forward to your feedback on the new WIKO® REPAIR UF adhesives. Your GLUETEC customer advisor will be happy to answer any further questions and take orders: info.de@gluetec-group.com, Tel. +49 9369 9836-0.